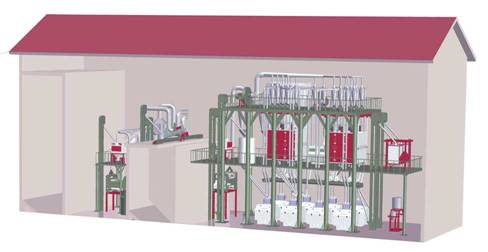

Steel-Constructed 80 to 150 t/d Flour Mills

In the steel-constructed series of complete flour mills, the M method was utilized in the design of the milling process. In this method, the equipment is assembled in a stacked up and down structure. The roller mill, flour receiver and bran receiver are located in an elevated position; the high-plane sifter and blower are below this; and the air seal and cyclone are constructed in the bottom-most position. The machinery for the 80 to 150 t/d flour mills have a compact structure, are easy to install and operate, and require minimal investment, making it the best choice for medium and small flour plants.

|

Model |

Type |

Model & No. of Mills |

Processing |

Capacity (t/d) |

Power (kW) |

Dimensions (L×W×H)(m) |

|

6FTFD |

Steel structure |

50×2/8 |

4B, 6M, 1S, 1T, 2BrF, 4P |

80 |

230 |

22×8×10 |

|

6FTFD |

Steel structure |

50×2/10 |

4B, 6M, 2S, 2T, 2BrF, 4P |

100 |

270 |

26×8×10 |

|

6FTFD |

Steel structure |

60×2/10 |

4B, 6M, 2S 2T, 2BrF, 4P |

120 |

340 |

30×8×10 |

|

6FTFD |

Steel structure |

60×2/8 |

4B, 7M, 2S, 2T, 3BrF, 4P |

150 |

380 |

33×8×15 |